Ingo B Hagemann

Note To Readers: The potential of this technology IOHO gives a whole new definition to the term “Smart Building”. “Great moments are born from Great Opportunity.” (H.Brooks: 1980 “Miracle”)

Ingo B Hagemann, architect and building-integrated photovoltaic (BIPV) consultant, discusses opportunities and challenges for organic solar cells and other third-generation photovoltaic (third-gen PV) technologies in the building and construction industry.

Until now, PVs have been developed and perceived simply as systems for generating electricity, with the performance of cells being defined purely in terms of power output.

Until now, PVs have been developed and perceived simply as systems for generating electricity, with the performance of cells being defined purely in terms of power output.

However, this is changing. In the future solar electricity production will become a by-product of multifunctional building components with integrated PV capability. Beside solar power output, the technology will be judged on other criteria, such as design and structural integration flexibility.

Organic PVs (OPVs) and dye-sensitised solar cells (DSSCs), which are collectively referred to as third-generation PV technologies (third-gen), have the potential to contribute significantly to this development. As third-gen PV technology advances in terms of performance and other factors, architecturally attractive uses of PVs in the building fabric will become more commonplace.

Unlike bulky and rigid traditional, silicon-based solar cells, third-gen PVs can be made lightweight, flexible and translucent. They can be produced in different colours and patterned, resulting in additional smart design opportunities for the integration of the PV  into the building shell.

into the building shell.

The new design features of third-gen PV correspond well with current trends in architectural design, such as an intensive use of colours, the use of (multimedia) screens and patterns for building façade designs. The technology also supports the rediscovery of the moulding of complex curving forms, which is a result and expression of contemporary architectural practice in which digital technologies are radically changing the way how buildings are conceived, designed and produced.

Printing, coating, vacuum processing and other simple, low-temperature and low-cost production processes are being developed to fabricate third-gen PVs, which will make them less costly to manufacture.

The benefits and advantages of third-gen PV for building and construction applications can be separated in to five main areas:

The benefits and advantages of third-gen PV for building and construction applications can be separated in to five main areas:

Good power performance under dim or variable lighting conditions

The power output of third-gen PV technologies is not so dependent on the access of direct solar radiation, compared with silicon, suggesting high performance under low light conditions such as fog, partially shaded building surface areas or indoors. This makes third-gen PV an ideal candidate for cloudy or smoggy environments such as major built up cities, where low light conditions are commonplace; in equatorial areas, where lots of clouding is caused by the Intertropical Convergence Zone (ITCZ); or in high latitudes, where overcast skies are typical. In addition, third-gen PVs can be developed for certain types of indoor applications, like powering emergency lights or motion detectors.

Power performance without cooling

Power performance without cooling means third-gen PVs can be used as an integral part of ‘sandwich’ building elements, which do not usually provide the option of back-ventilation for the integrated PV.

Sandwich elements allow for a wide variety of material combinations. Several variations are used in the building industry. Examples are structural insulated panels (SIPs), precast insulated roof systems – used often in home construction – or floor-to  floor façade elements used for the bracing of curtain wall façade systems.

floor façade elements used for the bracing of curtain wall façade systems.

Together with modern construction processes using assembly line automation, prefab sandwich elements meet today’s requirements of fast installation processes and heat insulation, while allowing for high standards of accuracy.

Design flexibility due to low-cost materials and easy-to-handle processing technologies

The global construction industry is diverse and the types of building products and materials it uses vary considerably. Construction methods and traditions, building products and building codes differ from country to country, even region to region. Unlike standard PV modules, it is not possible to design building products – with or without integrated PV – likely to serve a market on a global scale. However as third-gen PVs could be made using more straightforward, low-temperature production methods such as roll-to-toll on flexible substrates, the financial and technological effort needed to make these cells is much lower, compared with established first- and second-gen crystal and thin-film PV cells.

Therefore third-gen PV has the potential to open up the market for building-integrated PV products that serve the needs of regional building markets.

Transparency and durability

Glass is one of the most popular and durable building materials today, allowing for buildings to be designed with large window openings to exploit natural light. Glass can be engineered to meet the increasing façade performance expectations of the building envelope, with regards to heat insulation (U-value), noise, sun protection and weather protection and durability.

Rapid developments in the field of new coatings for glass, new material combinations with glass and associated new engineering, production and construction methods ensure it will continue to be a key component in building construction. In addition glass has a relatively small impact on the environment.

Rapid developments in the field of new coatings for glass, new material combinations with glass and associated new engineering, production and construction methods ensure it will continue to be a key component in building construction. In addition glass has a relatively small impact on the environment.

Essentially, minerals are used to produce a benign product. Theoretically, glass is infinitely recyclable with no loss of quality. These features make it a first-class, ecological building product for today and tomorrow.

Flexible and lightweight

Third-gen PV made from flexible and transparent substrates and encapsulation materials can provide a product with a combination of performance characteristics that do not yet exist on the building market. So-called plastic OPV cells can be lightweight, translucent and available in different colours, such as Konarka’s Power Plastic. OPvs offer integration opportunities for all kinds of building structures where a lightweight form factor is of structural importance, such as canopies and awnings, light roof construction of factory buildings and sports stadiums.

A field of special interest for the application of this type of third-gen PV is tension membrane or pneumatic cushions structures, which have increased in importance in modern architecture. They exploit daylight, while at the same time sheltering large façade areas. At night, PV structures could be illuminated by LED lights and designed to catch the attention of the public like other multimedia façades.

These low resource-demanding structures satisfy aspects of modern and sustainable architecture and third-gen PV solar electricity production adds functionality without interfering in design elements and properties. Well-known examples of these structures – without PV – are the Allianz Arena in Munich, the façade of the Burj Al Arab in Dubai, or the Olympic Swim Stadium in Beijing, China.

These low resource-demanding structures satisfy aspects of modern and sustainable architecture and third-gen PV solar electricity production adds functionality without interfering in design elements and properties. Well-known examples of these structures – without PV – are the Allianz Arena in Munich, the façade of the Burj Al Arab in Dubai, or the Olympic Swim Stadium in Beijing, China.

Challenges

Despite these advantages, third-gen PV efficiencies lack in comparison to conventional PV. But it can be expected that further technology improvements will increase over the next few years. Low production costs will help to neutralise low efficiency issues, since there are applications for BIPV where cost is the prime concern – such as the coating of large quantities of glass or the covering of large building surface areas with one type of material only.

A bigger challenge is improving the relatively short lifetimes of third-gen PVs. Due to established cycles for the renovation of building exteriors as well as liability issues – which architects, consulting engineers and construction companies must adhere to – the lifetime of BIPV product components must achieve 20-30 years.

In conclusion, the anticipated novel design opportunities and technical performance characteristics associated with third-gen PVs make them especially attractive for architectural applications. However, it also needs to be made clear that any meaningful  integration of these technologies in the building fabric will only arise from holistic planning and design approaches, which link the necessary power-engineering demands to the numerous existing and increasing requirements for building enclosures, architectural design and urban planning.

integration of these technologies in the building fabric will only arise from holistic planning and design approaches, which link the necessary power-engineering demands to the numerous existing and increasing requirements for building enclosures, architectural design and urban planning.

The properties desirable for a solar cell as part of an integrated structural product must be specified and consistently developed. The development of such BIPV products needs application-oriented research, to ensure products are meet practical requirements in a building.

The first- and seconnd-generation PV industry is still focused on bulk production, to benefit from mass production. But to meet the demands of an upcoming BIPV market, the low cost and flexibility of third-gen PV production provides a unique opportunity for the PV industry to make a transition to flexible production processes. Such a step would allow the PV industry to offer a structural and design flexibility for their BIPV products, which will provide architects the opportunity to create individual and alternating BIPV designs solutions

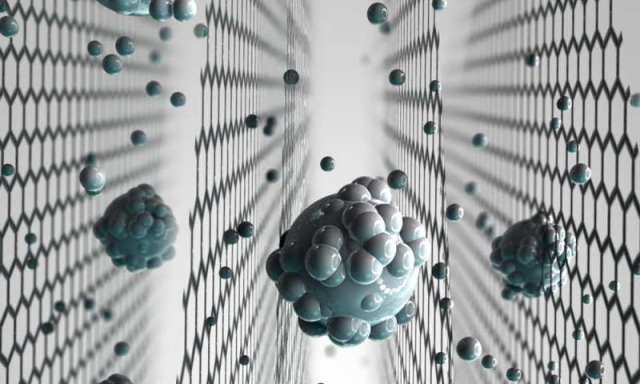

A graphene membrane. Credit: The University of Manchester

A graphene membrane. Credit: The University of Manchester World Economic Forum: Can Graphene Make the World’s Water Clean?

World Economic Forum: Can Graphene Make the World’s Water Clean?

Until now, PVs have been developed and perceived simply as systems for

Until now, PVs have been developed and perceived simply as systems for  into the building shell.

into the building shell. The benefits and advantages of third-gen PV for building and construction applications can be separated in to five main areas:

The benefits and advantages of third-gen PV for building and construction applications can be separated in to five main areas: floor façade elements used for the bracing of curtain wall façade systems.

floor façade elements used for the bracing of curtain wall façade systems. Rapid developments in the field of new coatings for glass, new material combinations with glass and associated new engineering, production and construction methods ensure it will continue to be a key component in building construction. In addition glass has a relatively small impact on the environment.

Rapid developments in the field of new coatings for glass, new material combinations with glass and associated new engineering, production and construction methods ensure it will continue to be a key component in building construction. In addition glass has a relatively small impact on the environment. These low resource-demanding structures satisfy aspects of modern and sustainable architecture and third-gen PV solar electricity production adds functionality without interfering in design elements and properties. Well-known examples of these structures – without PV – are the Allianz Arena in Munich, the façade of the Burj Al Arab in Dubai, or the Olympic Swim Stadium in Beijing, China.

These low resource-demanding structures satisfy aspects of modern and sustainable architecture and third-gen PV solar electricity production adds functionality without interfering in design elements and properties. Well-known examples of these structures – without PV – are the Allianz Arena in Munich, the façade of the Burj Al Arab in Dubai, or the Olympic Swim Stadium in Beijing, China. integration of these technologies in the building fabric will only arise from holistic planning and design approaches, which link the necessary power-engineering demands to the numerous existing and increasing requirements for building enclosures, architectural design and urban planning.

integration of these technologies in the building fabric will only arise from holistic planning and design approaches, which link the necessary power-engineering demands to the numerous existing and increasing requirements for building enclosures, architectural design and urban planning.

You must be logged in to post a comment.